Recently I decided to finally put to use the things I’ve learned during the development of my graduation project (read my previous post to know a bit more about it) and start my very own personal mini digital factory. At this point, I don’t know exactly what I’m aiming for, but I feel an urge to fabricate my own solutions like never before.

After giving some consideration to my options, it only seemed natural begin with an extrusion printer, considering that:

- I’ve been wanting one since 2009.

- That I never had the pleasure of 3d printing anything. I mean, I’ve seen it happen many times – mostly Yoda busts, company logos, complex geometric solids and other meaningless/useless objects meant only to wow as most viewers as possible into buying the product – but it’s not the same as seeing something you envisioned digitally being brought to physical existance. Additionally, I’ve also been offered the opportunity to print something of my own making, but the idea of handing my designs to someone else in order to get it fabricated is also unappealing to me. To me it’s part of the satisfaction to be involved in the process, to master techniques and configurations on my own, with plenty of time to observe, learn and come up with new insights while I do it.

- I have several projects, annotations and ideas of problems I’d love to design solutions for or things I’d like to have that doesn’t exist that 3d printing would help me build with more advantages than other techniques such as milling and . A few examples of such are presented in the images below.

Sliding doors lock is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Sliding doors lock is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Peanut skins sucker is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Peanut skins sucker is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

External HD hidden storage is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

External HD hidden storage is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

External HD hidden storage is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

External HD hidden storage is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License. (I’ll post these and other designs to Thingiverse or similar hosting service once they’re printed and tested.)

Picking a model.

As a person who has a very hard time making choices, though, the most troublesome stage of my endeavour was actually to decide which model to acquire and build. I’ve studied some of the Reprap models back when I discovered them, therefore I knew more or less what to expect and where to get some national replacements to the parts that, if imported, would raise the final cost.

Delta printers (more specifically the Rostock mini, elegantly derived from Johann’s Rostock design) seemed like the best choice. While horizontally the printing area is limited to the size of the heated bed, its vertical printing area is huge and apparently expandable. Recently I’ve found another remix of this model that expands delta printers advantages even more: Thingystock. A printer that promises to allow expansions in both vertical and horizontal printing space.

Nevertheless, although delta models looked really slick and seemed to offer many advantages over others, the strange 3-axis extruder positioning system didn’t appear to be a project someone with my level of knowledge should undertake. Besides, every delta printer model I found was not mature enough which would also force me to make uneducated choices that could cripple the outcome of my little project.

Another issue to me was the cost. Since I’m going to use it to make money, it seemed appropriate to minimize the required investment as much as possible.

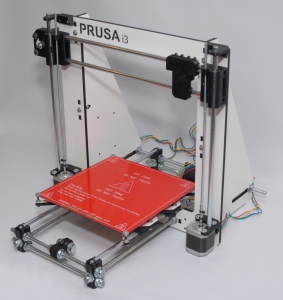

After taking all these variables into consideration and browsing online for what was more easily available to us Brazilian folks, I finally purchased a Reprap Prusa I3 from Dealer Extreme. It was meant to be a Christmas present, so I paid around $494 for it. Had I waited until now, I’d have saved a hundred bucks as it’s costing $395, but it was a good deal anyway, assuming the quality isn’t too low. We’ll see…

Congratulations on your new printer! My own printer is a reprap in the same price range as yours and I’m proud to say that with practice I’ve gotten to the point where I can just use the machine for ‘set and forget’ high quality prints without having to constantly maintain it. Just thought you’d like to hear that it is possible because when you first get started it can seem a little overwhelming. Also, I love your articles so far!

Thank you for sharing a bit of your experience, Mike. I’m really relieved to hear that even for cheaper printers, a certain quality and predictability of the output are attainable.

You seem to have written some interesting material yourself! I’ll definitely drop by to read and comment as soon as I have a little spare time.